Weidy · High-/Low-frequency Ceramic Capacitor Family of Products

Each capacitor has passed electrical performance testingWeidy · 6T Technology Reconfiguring Product Performance

Manifestation of 5G technology

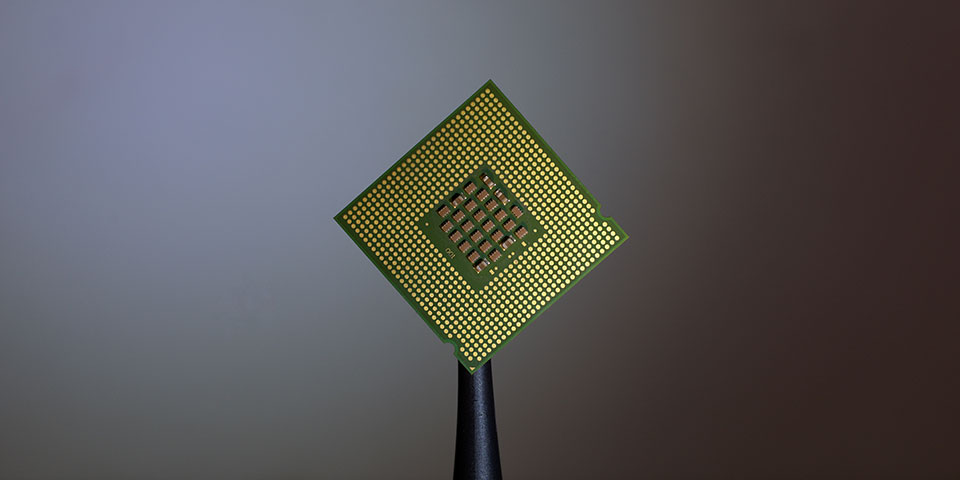

Special chip design

Additional grooves or protrusions at ceramic edges to extend the discharge path and effectively make the edge electric field uniform.

Additional grooves or protrusions at ceramic edges to extend the discharge path and effectively make the edge electric field uniform.

Anti-offset soldering

The soldering is specially designed to ensure the central placement of the chip and prevent offset.

The soldering is specially designed to ensure the central placement of the chip and prevent offset.

High-pressure plastic sealing

Compared with the ordinary hot melt encapsulation, this product adopts high-pressure plastic sealing, making it more dense.

Compared with the ordinary hot melt encapsulation, this product adopts high-pressure plastic sealing, making it more dense.

Full-inspection voltage-resistance testing

One-to-one testing of instruments and products to ensure the testing validity.

One-to-one testing of instruments and products to ensure the testing validity.

Marking, printing, and CCD visual inspection synchronization

Product marking, printing, and CCD visual inspection synchronization.

Product marking, printing, and CCD visual inspection synchronization.

Automated test packaging

Products are automatically tested and packed to replace manual operations

Products are automatically tested and packed to replace manual operations

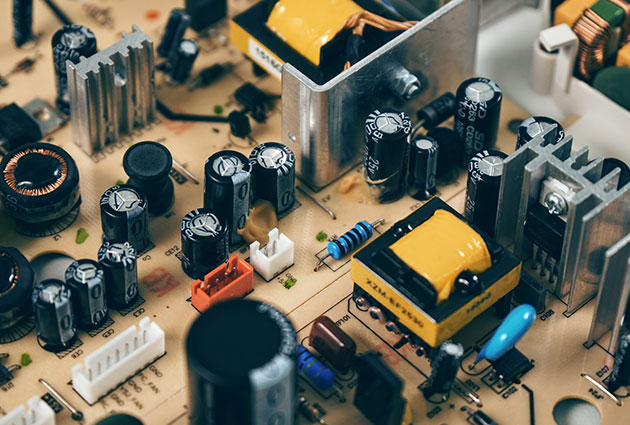

Demystified · A High-/Low-frequency Ceramic Capacitor's Process Journey

From incoming materials inspection to the finished products, our capacitors pass through 16 process steps to ensure the quality at each point

2raw

materials selections

5fine

processes

3major

production processes

4detail

treatments

6quality

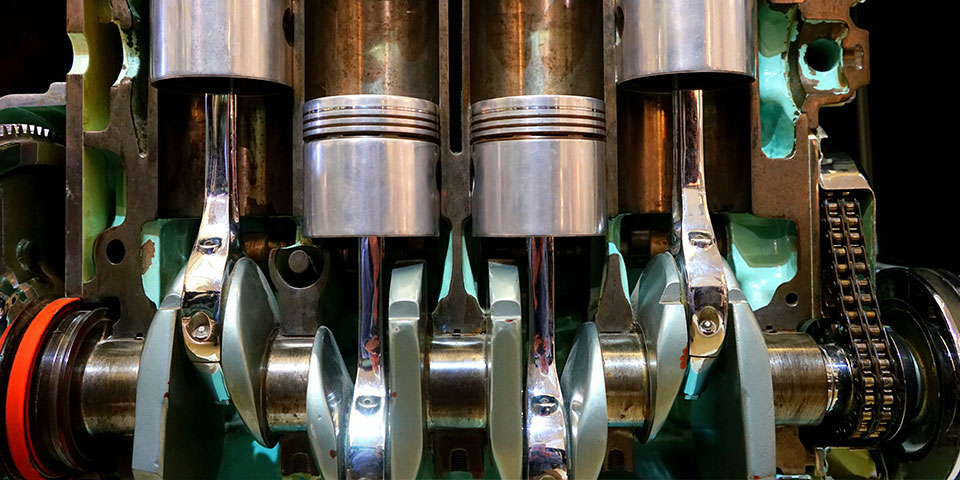

testsHigh-/Low-frequency Ceramic Capacitors · Panoramic Structure Diagram

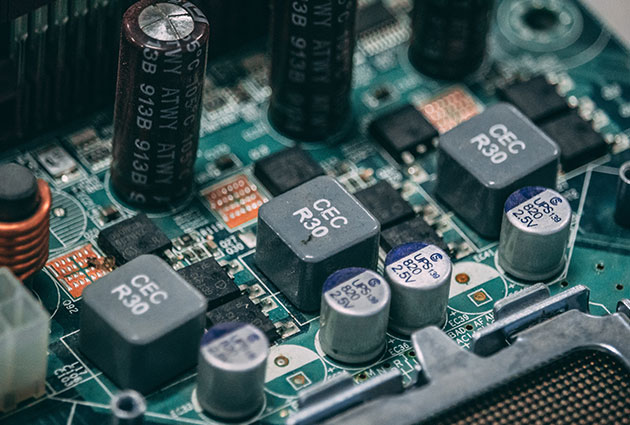

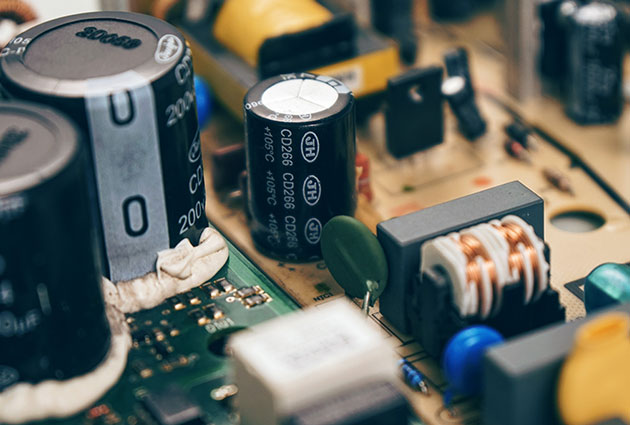

Where there is a circuit, there is a capacitor to suppress electromagnetic power interference

Product Structure

Product Structure

Product Structure

Weidy High-/Low-frequency Ceramic Capacitors · Complete Industry Certification

Numerous quality verifications, safe and reliable, diligently making quality products

Enterprise Strengths

Contact Us

About Us

Scan code 5 seconds

Scan code 5 seconds