Material selection

Processing and material selection plans for product reconfiguration

Design

Product design and structural design, and customer solution design reconstruction

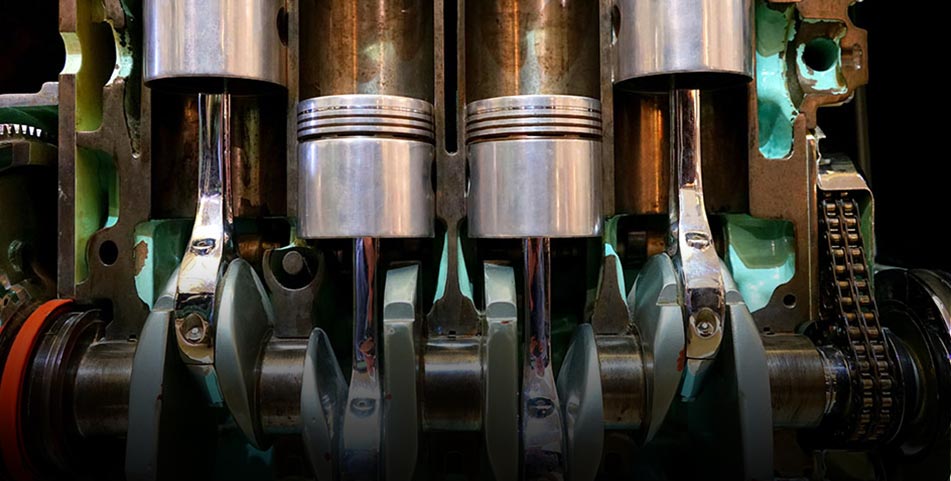

Hot pressing

Flattening and nesting to shape the product

Baking

105-120° high-temperature heat treatment

Metal spraying

Uniform spraying, auxiliary connection

Curing

Metal spray sealing, curing, and exterior encapsulation

Burr treatment

Uniform burr treatment

Aging

Product aging

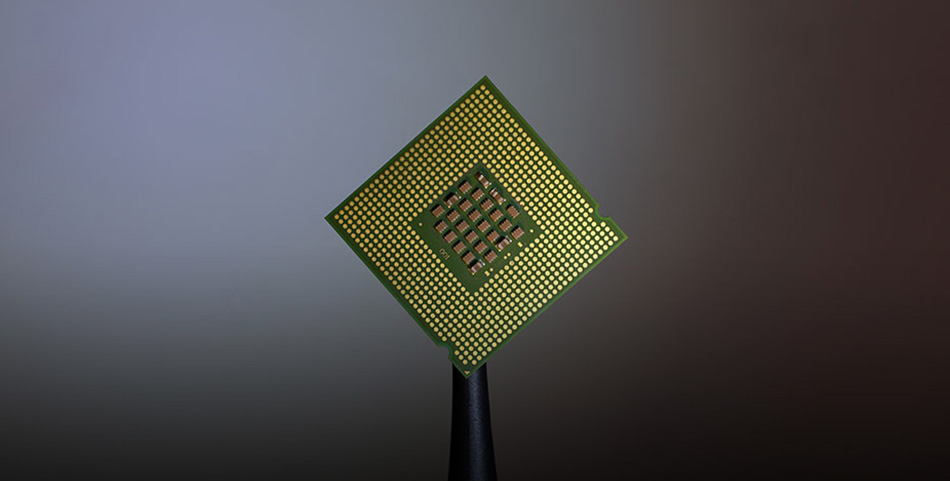

Soldering

Special soldering, ensuring chip central placement and preventing offset

Printing

Clear laser printing of model numbers, parameters and logos

INDUSTRLAL electronic

INDUSTRLAL electronic

Scan code 5 seconds

Scan code 5 seconds